However, understanding the distinct characteristics of wheels and casters is vital to making an informed decision. This guide will explore various factors involved in selecting the most suitable rolling components to meet your mobility needs.

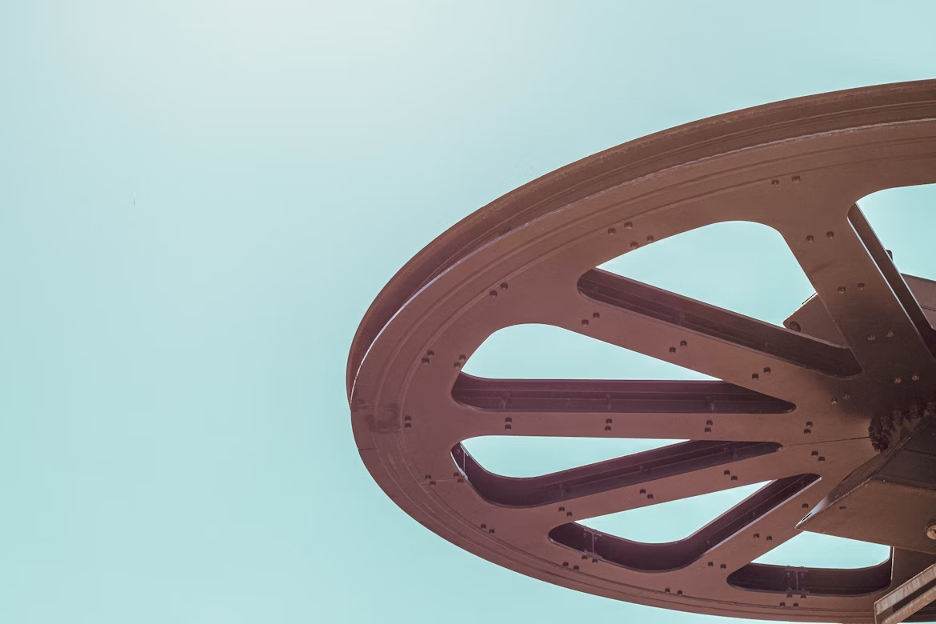

Understanding the Differences Between Wheels and Casters

Each rolling component serves its unique purpose, and understanding their differences is crucial. Wheels primarily support weight and allow for movement in a straight line. They consist of a circular disk that rotates about an axle. Depending on the design, wheels can be used in countless applications, from vehicles to dollies.

Casters, on the other hand, are wheels mounted on a frame that allows for additional movement, typically in more than one direction. They contribute to greater maneuverability, making them ideal for applications requiring frequent directional changes.

A hospital bed uses casters to move easily through narrow hallways. When you compare wheels vs. casters, you discover that the choice depends on specific requirements, including weight distribution and travel pathways. In practical usage, consider the workspace; tight environments may benefit from casters that offer enhanced flexibility, while open spaces may simply require wheels for linear movement.

These components serve different tasks, reiterating the importance of selecting the appropriate item based on intended function.

Load Capacity Considerations

Understanding load capacity is vital when selecting between wheels and casters. Every component has a specified weight limit, and exceeding this can lead to premature wear or failure. Ensure to calculate the total weight of the items being moved, including any additional load during operation.

Wheels generally have defined weight ratings that correspond to their size and material. A larger wheel typically supports more weight than a smaller wheel, thanks to its size and surface area. Casters come with weight ratings, but factors such as their frame design and mounting type affect their load-bearing capabilities.

The material of both wheels and casters plays a significant role in determining their load capacity. Rubber wheels can handle shock and provide a smoother ride, whereas hard plastic wheels may be more suitable for flat surfaces but offer less compliance under heavy loads. Keep in mind the environment where the rolling components will be used.

The surface type, whether it's smooth concrete, carpet, or rough terrain, affects both the performance and durability of wheels and casters. Be sure to consult manufacturers’ specifications for precise load-bearing capacities, ensuring a proper match between components and application needs.

Surface Compatibility and Floor Protection

Another important aspect to take into account when selecting rolling components is surface compatibility. Different wheels and casters are designed for various floor materials. Hard wheels, such as those made from plastic or metal, can cause damage on softer surfaces like wood or tile, potentially leading to scuffs and scratches.

Soft wheels made from rubber or polyurethane minimize damage and are better suited for delicate surfaces. They absorb shock, which can offer benefits in noise reduction as they traverse floors. Make sure to match the wheel or caster material with the intended flooring to prevent future maintenance issues.

The total weight of the application impacts whether you need a larger caster with a broader surface area. Wider wheels distribute weight more evenly, which is important for minimizing any floor damage.

Think about whether the application requires maneuverability, as selecting the right surface impact will ensure that rolling components perform effectively without compromising the floor's integrity.

Environmental Factors and Durability

Different environments pose unique challenges for rolling components. Factors such as temperature fluctuations, exposure to chemicals, and humidity levels can affect performance and longevity.

Outdoor environments require components that withstand rust and extreme temperatures. Material selection greatly influences durability under environmental stress. Stainless steel casters may perform optimally in wet environments where corrosion is a concern, while rubber wheels may degrade quickly in high-temperature scenarios.

Evaluating environmental conditions before choosing a wheel or caster ensures that it will endure the wear and tear of its setting. In a manufacturing or warehouse environment, the risk of exposure to chemicals demands the use of specialized materials.

Chemical-resistant wheels and casters can prevent failure due to exposure, ensuring reliable operation in demanding contexts. Determine the specific environmental challenges your application will encounter, and base your rolling component selection on your findings.

Ease of Maintenance and Replacement Options

Selecting rolling components involves assessing their maintenance requirements. Regular maintenance can prolong the life of wheels and casters, making it vital to choose options that allow easy access for maintenance. Ideally, components should allow for simple cleaning and inspection without significant disassembly.

Wheels and casters often come with different bearing types, each with varying maintenance needs. Sealed bearings require less maintenance compared to open bearings. When evaluating replacement options, ensure that the components are readily available.

Choosing standard sizes can facilitate easier replacement when necessary. In applications where downtime impacts productivity, consider implementing a periodic inspection schedule to catch potential issues early.

This proactive approach helps maintain efficiency and safety, ensuring that your rolling components continue to perform effectively. Take into account the expected lifespan of the component. Longevity in less intensive applications might warrant a more straightforward selection process.

Customization and Specialized Requirements

Sometimes, the standard wheels or casters may not meet specific requirements. In such cases, customization becomes paramount. Look for manufacturers that offer customizable options to meet distinct needs, such as non-marking materials, specialized sizes, or color-coding for identification.

For specialized applications, companies may provide custom solutions tailored to unique needs, enhancing performance and compatibility. Examples include medical equipment that requires quieter operation or industrial machines that need specific weight handling.

Working closely with suppliers can lead to solutions that surpass standard offerings, maximizing efficiency and safety for a broad range of applications. Understand that these custom solutions may come with price premiums; however, they can yield long-term savings by increasing the lifespan and reliability of the chosen components.

You'll be better able to locate the ideal fit if you evaluate how each rolling component aligns with various use cases. Choosing the appropriate rolling component is important for ensuring efficient mobility in any application.

Evaluate the differences between wheels and casters based on load capacity, floor compatibility, environmental factors, and maintenance needs. Custom options can further enhance performance. All these considerations will guide you towards making an informed decision that optimizes usability and extends the lifespan of your mobility solutions.