The manufacturing sector universally grapples with low production efficiency and difficulties in cost control. Traditional machining methods, reliant on manual processes, result in high error rates, leading to project delays and significant resource waste. The core issue lies in technological stagnation, where existing workflows fail to meet the stringent precision demands of increasingly complex components. To address these challenges, the adoption of high precision CNC milling technology emerges as a pivotal solution.

By leveraging digitalization and automation for precision machining, it fundamentally enhances production consistency and efficiency. The following analysis will delve into how CNC milling serves as a critical driver for modern manufacturing.

H2: Why is Precision Manufacturing the Cornerstone of Industrial Automation?

Precision Manufacturing forms the core pillar of Industry 4.0 and smart factories, ensuring that components essential for automated systems possess exceptional reliability and interchangeability. According to a report by the International Federation of Robotics (IFR), the global trend in automation growthremains robust, a phenomenon underpinned by the support of advanced precision manufacturing technologies. CNC Machining, for instance, is vital within the Automotive Industry. The machining precision of engine blocks or transmission gears directly impacts vehicle performance and longevity.

By controlling critical part tolerances to micron-level specifications, processes like CNC milling significantly reduce assembly failure rates and wear, thereby elevating overall product quality. A specific case involves a manufacturer utilizing five-axis CNC centers to machine complex curved parts, which boosted production efficiency by 40% while reducing the scrap rate by nearly 70%. This demonstrates that precision manufacturing is the essential foundation upon which efficient and reliable automation is built.

H2: How Does CNC Milling Enable Efficient Production of Automotive Components?

In the automotive manufacturing sector, efficiency and precision are inseparable. Precision CNC Milling technology is key to achieving this balance, capable of stably processing various complex components with extreme tolerances as tight as ±0.005mm.

H3: Seamless Formation of Complex Geometries

Modern automotive design, driven by lightweighting and performance optimization, results in parts with increasingly intricate structures. A CNC mill, with its multi-axis capabilities, can complete the precision machining of parts with complex surfaces and internal cavities—such as engine manifolds and turbine blades—in a single setup, eliminating errors associated with multiple fixtures.

H3: Maximizing Material Utilization and Energy Efficiency

Efficient production is not just about speed but also resource conservation. A study by the U.S. Department of Energy's Advanced Manufacturing Office on the reduction of material wastehighlights that optimized machining strategies can significantly reduce energy consumption and material usage. CNC milling maximizes raw material use and minimizes scrap generation through intelligent programming that optimizes tool paths.

-

Software Simulation and Pre-processing

Advanced CAM software allows for full-process simulation before actual machining, enabling collision detection and cutting parameter optimization to prevent errors and waste at the source.

-

Sustainable Manufacturing Practices

Reducing scrap directly lowers the demand for raw materials and disposal costs, aligning the production process with sustainable manufacturing principles.

H3: Quality Consistency and Standardized Certification

For safety-critical industries like automotive, consistency is paramount. Production lines employing CNC milling, integrated with quality management systems such as ISO 9001, ensure that the 1st and the 10,000th part possess identical accuracy and quality. This traceable and verifiable standardized production is the foundation of trust in the automotive supply chain. For a deeper dive into the technical details, one can refer to this comprehensive guide on Precision CNC Milling.

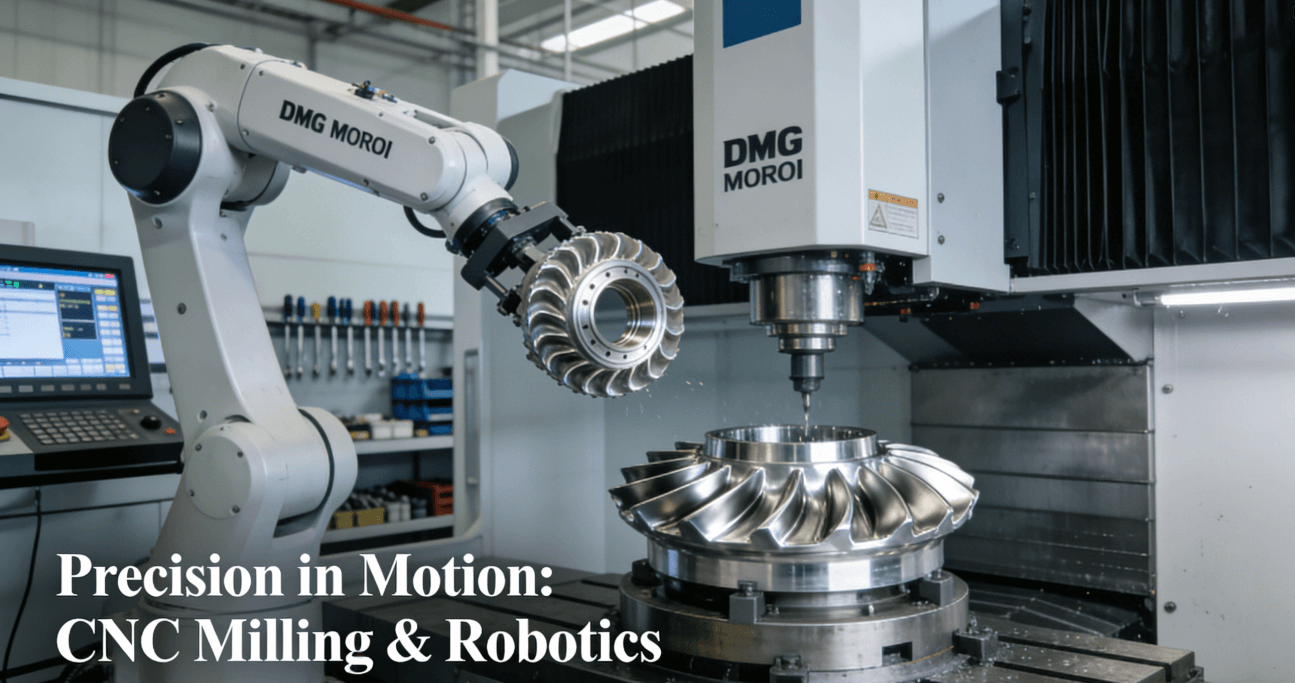

H2: What Are the Advantages of High Precision CNC Milling Machines in Robotics Automation?

The integration of high precision CNC milling machines with Robotics Automation systems forms the hardcore of modern intelligent manufacturing. This synergy creates unmanned or minimally manned flexible manufacturing cells with significant advantages.

The primary advantage lies in precision and reliability. The precision CNC milling machine executes ultra-precise cutting tasks, while robots handle auxiliary duties like loading, unloading, cleaning, and inspection. This combination enables 24/7 continuous high-precision operation, minimizing human intervention. It is particularly suitable for producing high-precision key components required by the Robotics Automation systems themselves, such as harmonic reducers and robotic joint arms.

Furthermore, real-time monitoring and data interoperability capabilities are greatly enhanced. Sensors on modern CNC machines provide real-time feedback on tool wear and temperature changes. This data interconnects with the robot control system and higher-level Manufacturing Execution Systems (MES). If an anomaly is detected, the system can automatically instruct the robot to change tools or adjust parameters, enabling predictive maintenance and reducing unplanned downtime.

In terms of long-term benefits, this integration, tested against stringent quality certifications like AS9100D, ensures stable output even in fields with extreme reliability requirements. It not only improves single-run production efficiency but also, through its digital and adaptive capabilities, lays a solid foundation for future trends like small-batch, high-mix production, achieving long-term manufacturing flexibility and competitiveness.

H2: Can Custom CNC Milling Services Adapt to Low-Volume Production Needs?

Absolutely. The core strength of modern custom CNC milling services lies in their exceptional flexibility, making them perfectly suited to the market's shift towards low-volume and customized production trends.

H3: Rapid Prototyping and Low-Cost Iteration

For the research and development phase, a key application within CNC milling applications is rapid prototyping. Companies can leverage external professional CNC milling services to obtain physical prototypes quickly without investing in large production lines, significantly accelerating the design validation cycle and reducing upfront development costs and risks.

H3: On-Demand Production and Zero-Inventory Models

-

Responding to Market Fluctuations

Custom services allow companies to produce based on real-time orders, avoiding the inventory pressure and capital tied up in large-scale material preparation. This is ideal for industries with fast product lifecycles.

-

Enabling Personalized Customization

From customized medical devices to limited-edition consumer goods, CNC milling can handle various low-volume personalized orders economically and efficiently, meeting niche market demands.

H3: Technology Democratization and Knowledge Empowerment

Service providers often educate users through content that explores informational long-tail keywords like "CNC milling applications." This not only helps clients understand technological boundaries but also enables them to specify requirements more accurately. Ultimately, by leveraging the service provider's professional equipment and process knowledge, clients achieve cost-effectiveness and quality superior to in-house production. Explore our services for high precision milling to begin your flexible manufacturing journey.

H2: Is a Mini CNC Milling Machine Suitable for Prototype Development in Startups?

For resource-constrained startups and R&D teams, a mini CNC milling machine is an attractive entry-level option. It allows for in-house rapid iteration of design concepts, significantly speeding up the process from idea to prototype.However, a balanced assessment of its pros and cons is essential. The advantages include low cost, small footprint, and relatively simple operation, making them well-suited for educational models or simple functional prototypes made from plastics or soft aluminum. Their limitations are clear: typically lower rigidity and power pose challenges when machining hard materials like steel; their accuracy and stability cannot match industrial-grade high precision CNC milling equipment, potentially failing to meet the performance testing requirements for final parts.

Therefore, a hybrid strategy is often adopted by startups: using a mini machine internally for early rapid iteration and team skill development, while outsourcing parts requiring final validation, small-batch pilot production, or high precision to partners with professional certifications like IATF 16949. For example, collaborating with a specialized manufacturer like JS Precision can bridge the gap in high-end equipment and process expertise, ensuring the quality of critical components. This allows the team to focus on core design and innovation rather than manufacturing bottlenecks, thereby enhancing overall R&D efficiency within the broader context of Robotics Automation.

H2:Conclusion

In summary, high-precision CNC milling technology, through its deep integration of automation and digital precision machining, has become key to solving manufacturing efficiency and quality challenges. It not only significantly enhances production consistency and reduces costs and resource waste but also empowers companies to cope with diverse market demands through flexible customization capabilities, thereby comprehensively enhancing industrial competitiveness.

Immediately explore custom solutions to optimize your production process and obtain a rapid quote.

H2:FAQ Section

Q1: What is Precision CNC Milling?

A1: Precision CNC milling is a computer-controlled machining process that uses rotating cutting tools to remove material with high accuracy, achieving micron-level tolerances. It is suitable for components with stringent requirements for dimensions, shape, and surface finish, ensuring exceptional consistency in mass production.

Q2: How does CNC Milling benefit Automotive Manufacturing?

A2: It enables the efficient and high-precision machining of complex core components like engine blocks and transmission gears, drastically reducing human error. It increases production speed and flexibility while lowering per-unit costs through automation, ensuring reliable, high-quality output for the automotive industry.

Q3: What are the main limitations of a Mini CNC Milling Machine?

A3: Mini CNC machines are primarily limited by their structural rigidity and motor power, resulting in lower accuracy, stability, and a narrower range of suitable materials (mostly non-ferrous metals and plastics) compared to industrial-grade equipment. They are ideal for prototyping but unsuitable for high-strength, high-precision end-use parts.

Q4: How do Custom Services guarantee quality?

A4: Professional custom services ensure quality through a comprehensive quality control system, including strict incoming material inspection, certified process management, real-time in-process monitoring, and final precise measurement. This guarantees every custom part meets design specifications, minimizing rework risks.

Q5: What is the future of CNC Milling in Automation?

A5: The future involves deeper integration with AI and the Internet of Things, enabling adaptive machining and predictive maintenance. Machines will automatically optimize parameters, compensate for errors, and seamlessly exchange data with the entire automation system, meeting escalating demands for flexibility, efficiency, and precision.